Integrated production system

An example of a “vertical startup” from prototype to mass production

Meetings Mold design Mold making Trial molding Injection molding

(mass production) Measurement inspection

Specification confirmation/Meetings

We accept inquiries about products in the conceptual stage. Field techni-cians can recommend product shapes, precision, and molding materials suit-able for your ideal product.

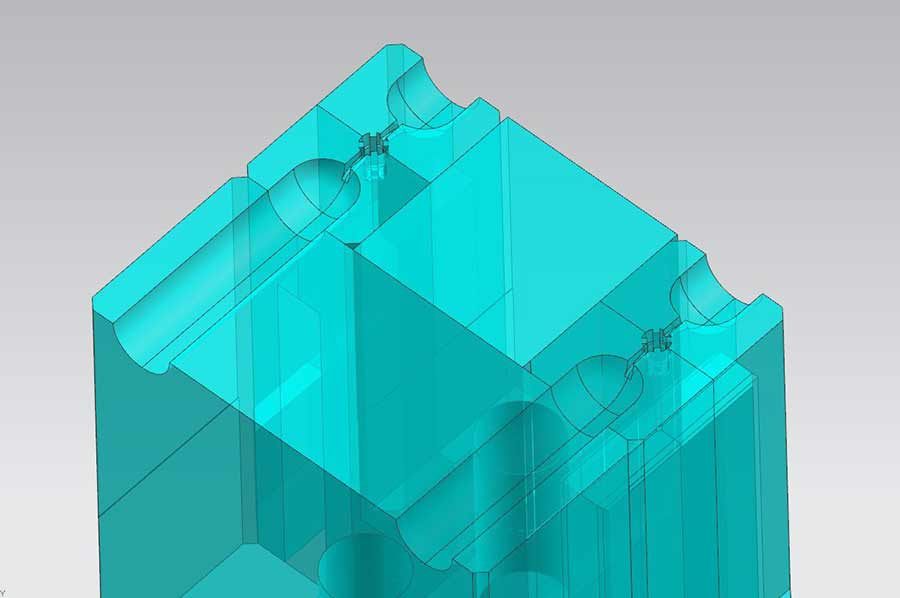

Mold design

The mold is designed by checking the product shape, shrinkage ratio, num-ber of products taken, gate position, etc. The corner radius and draft are added to prevent sink marks and warps so that high-quality injection mold-ing can be performed.

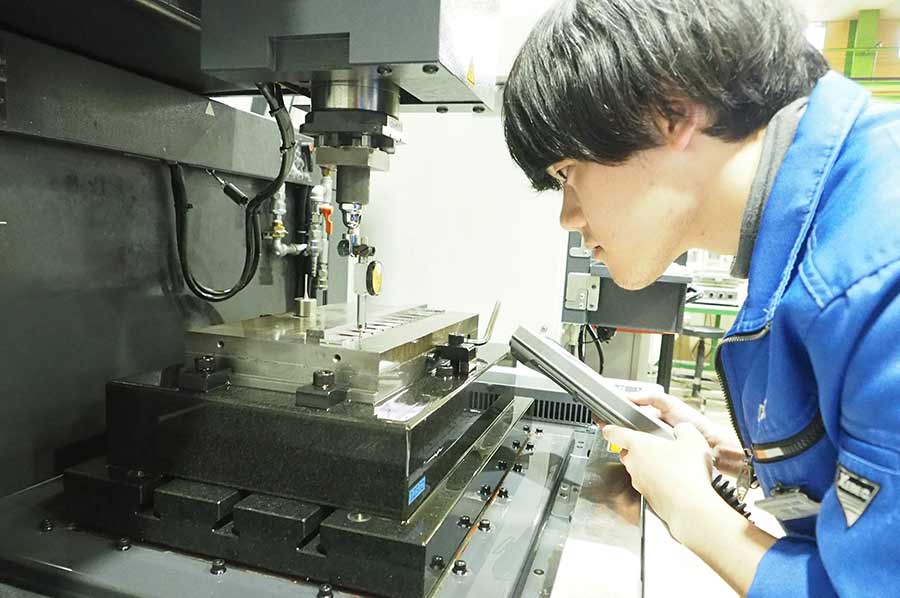

Mold making

We manufacture molds that require precision in μ units, such as mechanical parts. In our Mold Manufacturing Department, we mainly process parts for molds made by other companies and manufacture molds used by our Mold-ed Products Manufacturing Department, and we have a complete support system for repair and maintenance.

Click here for details.Trial molding

A molding test is performed after the mold is manufactured. Since G-Tech carries out integrated production, we will perform a first try in our Molded Products Manufacturing Department. Deficiencies found in the molding test are shared between the Molded Products Manufacturing Department and the Mold Manufacturing Department, and they will resolve the problem through quick cooperation.

Injection molding (mass production)

Since the molds manufactured by the Mold Manufacturing Department do not require relocating verification work. This means the molds can be mass-produced immediately. The delivery time can be shortened by 1 to 2 weeks compared to the normal relocation process.

Click here for details.Automatic visual inspection

In addition to the automated inspection equipment, we perform a visual in-spection on each piece. The inspection is performed not only on the dimen-sions, but also on the appearance and strength, as well as the product appli-cation. We assure quality control by checking product manual information on tablet devices and sharing defect information through the production management system.

Click here for details.