High precision molds

G-Tech takes orders for the processing of molded parts. We also have an in-tegrated production system that allows us to create the molds to the prod-ucts, and we believe we can meet the needs of our customers.

Features of injection molds

Fine shapes

High quality

High precision

Features of mold parts

Single item

High quality

Quick delivery

High precision

G-Tech's processing technology that produces high-precision molds

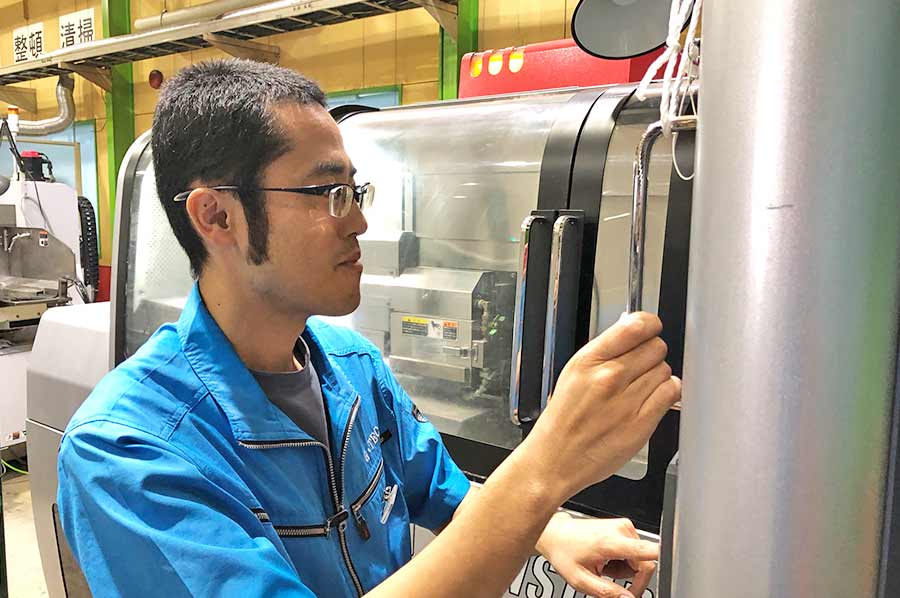

Point 1General purpose formed grinding machine

We make full use of the five senses of our craftsmen, finishing the process while being cognizant of the sensitive processing state. The accuracy of ± 0.5 μm has been achieved with the skill and intuition of our craftsmen that have been cultivated over many years.

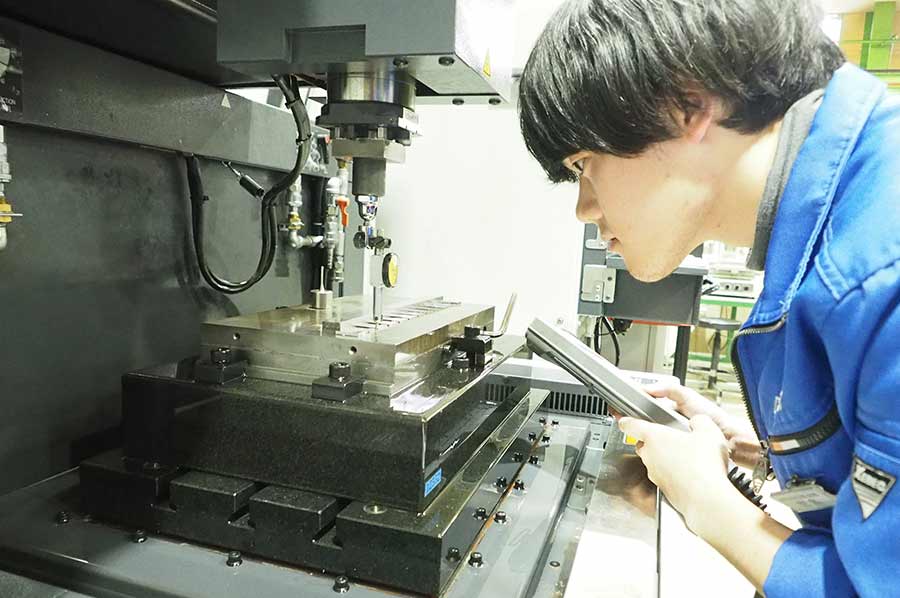

Point 2NC formed grinding machine

We perform high-precision groove processing and shape processing by mak-ing use of the high straightness and pitch accuracy of the machines. Also, complex composite shapes can be processed by using the contouring mode. It is possible for us to perform high-precision processing under optimal cut-ting conditions because we have many years of experience using the general purpose formed grinder which gives our craftsmen a high degree of tech-nique.

Point 3High speed milling center

High positional accuracy is achieved by the all-axis linear motor drive and high-speed, high-accuracy spindle. As a result, it is possible for us to mass produce highly accurate products without any imperfections. In addition to manufacturing discharge machining electrode, this machine is also used for direct engraving of high hardness materials. Also, the automatic work ex-change system enables the production of electrodes 24 hours a day.

Point 4Engraving electric discharge machine

Features such as the Z-axis cooling mechanism and thermal displacement correction maintain high accuracy, even during long-term operation. It is possible for us to process products in the same lot with the same quality by accurately processing products with high-precision electrodes.

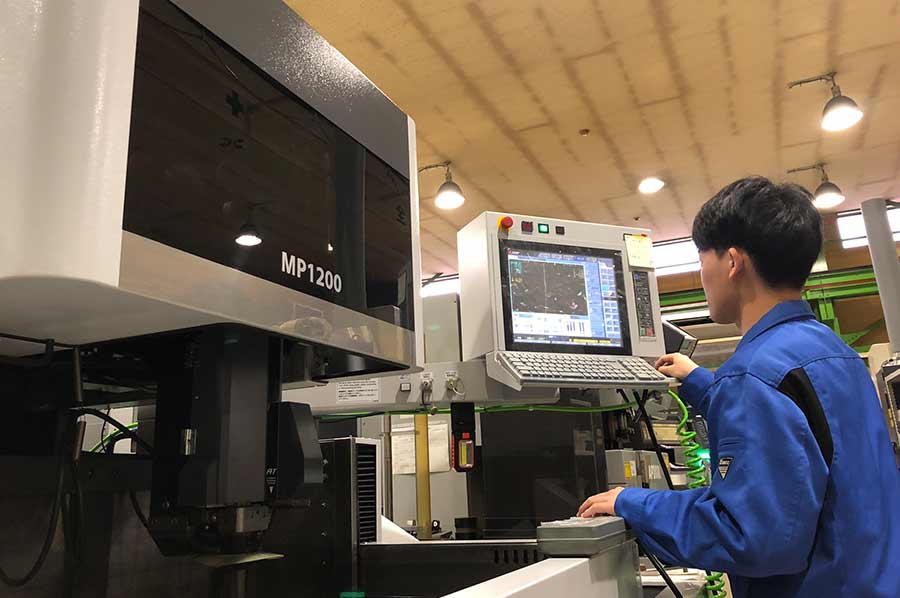

Point 5Wire electric discharge machine

The linear motor drive achieves high positional accuracy. With the best sur-face finishing circuit, it is possible for us to finish up to 0.6μmRz. Optimal corner control minimizes sagging in and out of corners. This makes it possi-ble to perform high-aspect-ratio processing without too much sagging. It is impossible to achieve the same level of processing by only using the grinding process.